BLACKMAILLE

Part 26 - Tailoring

by Lord Thomas the Black

BLACKMAILLE

TAILORING

Welcome back to another edition of “Blackmaille”! This month, I’m going to cover some common tailoring problems that mailers will run into, and the easiest, most pain-free way to solve them.

Before we begin, be aware that this will be the most picture-heavy article I’ve written yet, so it may take some time to load. The reason for this is two-fold: 1.) the techniques I’ll describe in this article will probably be a little hard to understand solely in text. Since I can’t be there to walk you through it in person, the pictures should clarify things a little. 2.) This article and next month’s (on tricky seams) are the result of an internal debate over whether or not I should re-write a chapter of my upcoming book (“Chainmaille in the Current Middle Ages”). It was decided that re-writing the chapter would be more trouble than it was worth, and writing these articles from scratch would be far easier.

For the purposes of this article, we’ll deal with the tailoring problems common to European 4-in-1 maille, as this was the most common type, and therefore, we have the most historical examples to draw from.

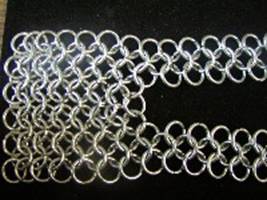

European 4-in-1 maille can be (and was) tailored in two directions: as the maille hangs up-and-down, and in the direction the rows of rings run, left-and-right. For our purposes, we’ll refer to these as the “X-axis” and the “Y-axis” (Fig. 1).

Fig. 1

Tailoring on the X-axis

This is by far the easiest direction in which to add or subtract rings. Most of your expansions and contractions will take place along this axis, particularly in the body of a hauberk (for example).

Expansions

Expansions on the X-axis are simplicity

itself. All you have to do is add a few rings into the row you wish to expand.

For example, in

Fig. 2, we have a simple chain of seven basic units (Fig. 2). I want the next

row to be longer, so I’ll add expansion rings to this row

(shown in brass for clarity) (Fig.3).

Fig. 2 Fig. 3

7-unit chain Expansion rings added

Now I’ll connect the next row as usual, and

the expansion rings will “stretch” the maille (Fig. 4). This is particularly

useful in standards and

coif tops, where the maille has to conform to a curved or round surface.

Fig. 4

Expanded maille

Contractions

Contractions on the X-axis are just as easy as

the expansions. Say you want to tailor a hauberk into a V-shape. As you weave

the maille

down

the body, you’ll need to make the next row down smaller in order to get that

taper. Again, we’ll start with our 7-unit chain (Fig. 5).

To make

the next row smaller, we’ll contract the bottom row. In this case, rather than

subtracting rings from the bottom row, we'll add

contracting rings (Fig. 6) that connect 3 rings, rather than the usual two.

Fig. 5 Fig. 6

7-unit row Contracting rings added

Then, we continue with the maille as usual, but the next row has less basic units, thanks to the contractions (Fig. 7). It’s just that easy.

Fig. 7

Contracted maille

Tailoring on the Y-axis

Expanding and contracting on this axis is a bit trickier, but a lot less common. Most often, you’ll see these tailoring techniques used in the sleeves of hauberks and on voiders, where the shape of the maille has to follow the contour of the arm.

Expansions and contractions both are what we call “whole row”, meaning you’ll either add (for expansions) or remove (for contractions) an entire row of maille. As a result, you’ll need less tailoring on the Y-axis than on the X-axis.

Expansions

Expansions on the Y-axis start with knowing

where you need to add a row. In this example, I have two rows of maille that

need to be

expanded to three.

I start by removing the connecting rings between the two rows (Fig. 8). Next,

I’ll add a row of rings on both the top

and bottom rows

(Fig. 9).

Fig. 8 Fig. 9

Connecting rings removed New rings added

Next, add another row of rings, connecting the

two at the joint (Fig. 10). Now, the sharpest of you will have noticed that the

row

you

just added will form the top and bottom rings of the third row that you wanted

to add! So, just join these rings as usual (Fig. 11),

and

you’re done!

Fig. 10 Fig. 11

Next row added 2-row to 3-row expansion completed!

Contractions

Contractions on the Y-axis are done similar

to expansions in reverse. In this case, we’ll be taking a 3-B.U. strip of maille,

and contracting it down to 2 B.U.’s (Fig.12). as you can see, I’ve laid out

where I’m starting, and what I want at the end.

Keeping your goals clear like this will make things easier later on. Now, I add

2 rings to the join, creating a triangle effect (Fig. 13).

Fig. 12 Fig. 13

3 B.U (left) to 2 B.U. (right) New rings added

Next, connect these two rings together,

pulling the maille in closer (Fig. 14). Now, add two more rings, hooking your

two outside

rows to the center ring (Fig. 15).

Fig. 14 Fig. 15

New ring added (center) Outside rows connected

Finally, connect your two rows to each other as usual, and continue down the row (Fig. 16), and you’re done!

Fig. 16

3-row to 2-row completed

6-in-1 Expansions/Contractions

Oddly enough, despite the added number of rings, expansions and contractions in European 6-in-1 are really not all that much different than in 4-in-1. The main difference is in how many rings the expansion/contraction rings must pass through. It just takes a little more attention to detail, however, and shouldn’t be that difficult.

NOTE: For the purposes of this article, I’m only going to cover expansions/ contractions on the X-axis. The reason for this is that Euro 6-in-1 was only used in period for the collars on standards and some hauberks. 6-in-1 was used because the denser weave would stand up on its own to protect the neck better. As a result, the only taper needed would be along the X-axis.

*** All of the demonstration pieces for this section were provided by my student, Miles Magus (MKA Louis Soetaert). ***

Expansions

To expand a strip of 6-in-1, we start with the

row to be expanded (Fig. 17). Next, starting with the end of the row, we count 4

rings over,

and add an

expansion ring. The difference between the 4-in-1 expansions and 6-in-1 is that

in 6-in-1, the expansion ring will pass through

two rings

instead of only one. Now count 4 rings and add another expansion ring, and so on

until you reach the end of the strip (Fig. 18).

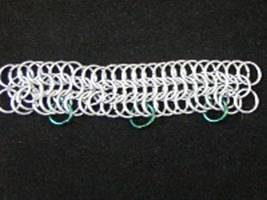

Fig. 17 Fig. 18

6-in-1 strip Expansion rings added

Finally, add the next row of 6-in-1 as normal,

counting the expansion rings the same as you did on the 4-in-1. The next row of

maille

will be longer, and the result

will look like this (Fig. 19):

Fig. 19

Expanded 6-in-1

Contractions

To contract a row of 6-in-1, you’ll follow

much the same process as you did to contract 4-in-1. However, where in 4-in-1 it

was

a

simple matter of contracting by 1 and ½ B.U.’s, in 6-in-1 it’s not quite that

easy. The odd number of rings in each basic unit adds

a new

challenge to this process. You’ll find that it’s a challenge that can be

overcome, though.

To contract 6-in-1, we’ll start with a strip

of 6-in-1 just as we did with the expansions (Fig. 20). To this we’ll add our

contracting

rings

(Fig. 21). The contracting rings take a little more attention here than they did

in the 4-in-1, because of the odd number of rings

in each

unit. Starting from one end of the row, count three rings over (that’s your

first BU), then three more rings (second BU), then

two

more, and put your first contraction ring through the second BU and the two

rings. Next, count three more rings over (1 BU space

between

contractions), then another three rings, then just one more ring, and put your

next contraction through these four. Continue

in this

fashion (5-ring then 4-ring contractions, with at least 1 whole BU’s between

them) until you’ve reached the end of the piece.

Fig 20 Fig 21

6-in-1 strip 6-in-1 strip with contractions

Finally, just add your next row of 6-in-1 as

usual, and you’re done (Fig. 22)! You’ll notice how the next row down is shorter

because

of the

contractions.

Fig. 22

Contracted 6-in-1

If this seems confusing, don’t worry too much about it. In reality, 6-in-1 contractions are rare, as 6-in-1 was usually used on the collars of hauberks and on standards, so the natural construction of it is to expand from the hem to the base, where the neck gets wider into the shoulders. You may never need to contract 6-in-1. I include it here for purposes of completeness.

Well, that wraps it up for this month’s “Blackmaille”. I had intended to have a section on odd seams, but as this article was already running eight pages and 22 pictures, I decided to cut it off here and write a separate article for the seams. So, join me next month for everything you ever wanted to know about odd seams, including how to join 4-in-1 to 6-in-1, hauberk armpit seams, and more! Thanks for joining me for another month!

Without Wax,

Lord Thomas the Black

of House Leatherwolf

“Artifax Ars Monstret”

Back to the Blackmaille Webpage

Back to the Cúm an Iolair Information Webpage

Articles: ©2003, 2004, 2005, 2006

Thomas Becket/Lord Thomas the Black

Hosting: ©2003, 2004, 2005, 2006

Ron Knight/Modar Neznanich

e-mail: modar@everestkc.net